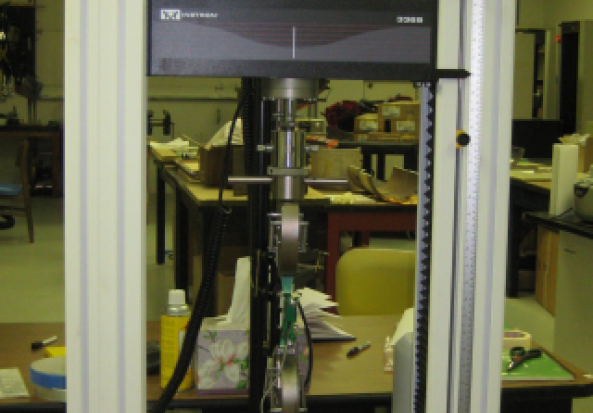

Instron 1342 Servo Electric Test System

The UTM (Instron 1342) is a servo hydraulic fluid controlled machine, consists of a two column dynamically rated load frame with the capacity of load up to 100kN (dynamic), hydraulic power pack (flow rate 45 litre/minute) and 8800 Fast Track 8800 Controller test control systems, fully digital, single axis controller with an

Contact Person/s